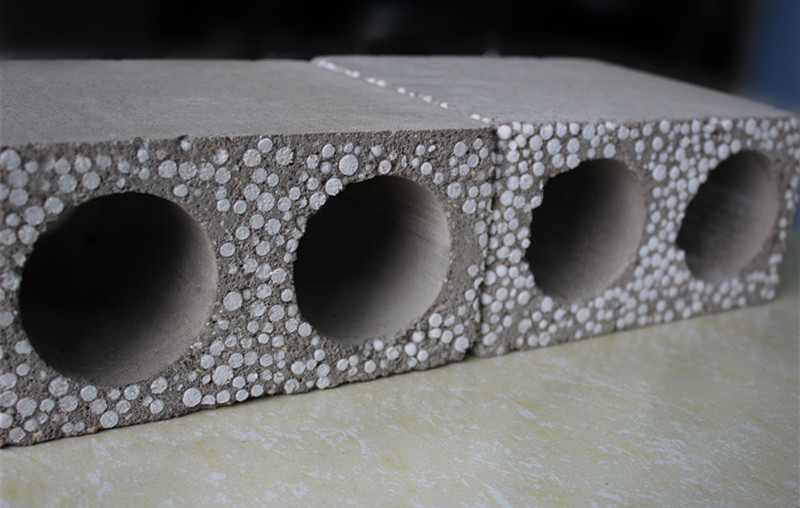

Eps & cement

hollow panel is a kind of lightweight energy saving hollow wall material,which

compound cement ,eps and sand by one time .This product is widely applied to

all kind of modern building for interior wall partition ,exterior wall and heat

preservation for the floor and roof with special and feature of light weight

and cost saving .

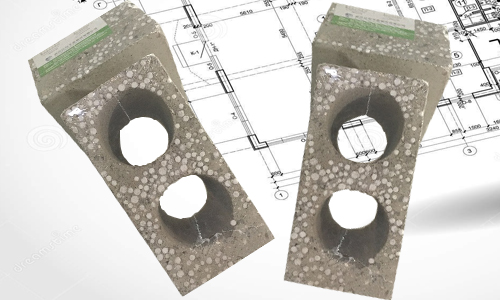

Application Range

1) Widely applied to

all kind of modern building for no-loading

interior wall partition and exterior wall .

2)Used as the exterior&interior partition wall,which have

slab loading bearing requirement in the old building renovation projects.

3)Applied to floor and roof

insulation

Site construction effect

Product features

1、 Energy saving, green

environmental protection

DQ

hollow core wall panel adopt anti-freezing and heat preserving environmental

protection materials with good heat insulation and preservation function ,which

could adjust the indoor temperature at a constant range ,thus achieving the

effects of ecological adjustment ,Keeping pace with the development of modern

ecological residential building.

2、Water proof ,fire

proof

DQ hollow core wall panel’s

incombustibility standard achieve national level A .Besides these raw materials give out no toxic gas and

perfectly meet the international environmental protection .

The tests also prove that water

containers can be made by using Daquan solid wall panel with no need for

plastering and the containers have no leakage at all .

3、 Sound insulation and

absorption

DQ solid wall panel has good sound

insulation and sound-absorbing functions

.

4、 lightweight ,space

saving ,cost saving

DQ hollow core wall panel is the new

type wall with core,the raw materials for wall panel is light and can reduce

the weight of building .The thickness of Daquan

hollow core wall panel are between 90mm to 180mm .They can increase the

building spaces compared to the traditional blocks.

5、 Easy construction and

shorter time

DQ

wall panel adopt assembly construction method ,the whole assembly or

construction process is simple, effective, no construction waste, no plaster,

shorten the construction period .The construction work with traditional

blocks taking 12 people 60 minutes to

complete will need only 3 people to spend 60 minutes to finish it if they use

Daquan boards which can save a lot of labor cost for construction part.

Product technical indicators

|

S/N

|

Items

|

National

standards

|

Testing

Indexes

|

|

90mm

|

120mm

|

90mm

|

120mm

|

|

1

|

Anti-impact

performance

|

≥5

|

≥5

|

>5

|

>5

|

|

2

|

Anti-bending

damage load/Times over dead weight

|

≥1.5

|

≥1.5

|

>2

|

>2

|

|

3

|

Anti-pressure

strength

|

≥3.5

|

≥3.5

|

>3.5

|

>3.5

|

|

4

|

Soften

coefficient

|

≥0.80

|

≥0.80

|

>0.8

|

>0.8

|

|

5

|

Surface

density

|

≤90

|

≤110

|

≤50

|

≤60

|

|

6

|

Moisture

rate

|

≤8-12

|

<8

|

|

7

|

Drying

shrinkage value

|

≤0.6

|

≤0.6

|

<0.6

|

<0.6

|

|

8

|

Single

point hanging strength

|

≥1000

|

≥1000

|

>1000

|

>1000

|

|

9

|

Sound

insulation capacity in the air

|

≥35

|

≥40

|

>35

|

>40

|

|

10

|

Fireproof

limit

|

≥1

|

≥1

|

>3

|

>3

|