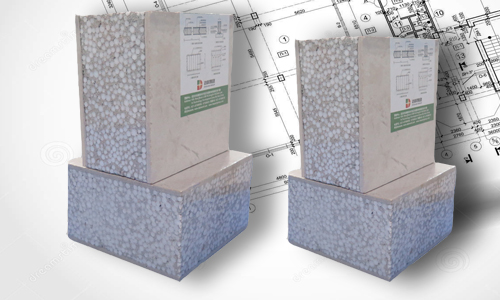

DAQUAN

waterproof wall panelis kind of lightweight wall material made of cement, EPS,

yellow sand as core materials and forming by one time compound. It has good function

on waterproof and moistureproof, which is good for moisture sites, such as

kitchen, bathroom, basement, the wall will not have such changes like

looseness, scumming, transformation and strength degradation.

Application range

1、widely used in all kinds of old and new construction of bearing

internal and external wall;

2、apply to office

buildings, residential, schools, hospitals, hotels, KTV etc, which has higher

requirements for sound insulation;

3、suitable for internal and external wall of steel structure

construction;

4、suitable for old building which has

high strict requirment for floor slab

Construction drawing

Product features

1、 Waterproof

Test shows

that DQ sandwich wall panel can be made as container for water withouth any

plastering, its totally no leakage of water.

It has

good function on waterproof and moistureproof, which is good for moisture

sites, such as kitchen, bathroom, basement, the wall will not have such changes

like looseness, scumming, transformation and strength degradation.

And in wet

weather, there will be also no condensed water bead on the wall, but for the

common wall, which is not moistureproof, so the stripping will be happen as

time goes by.

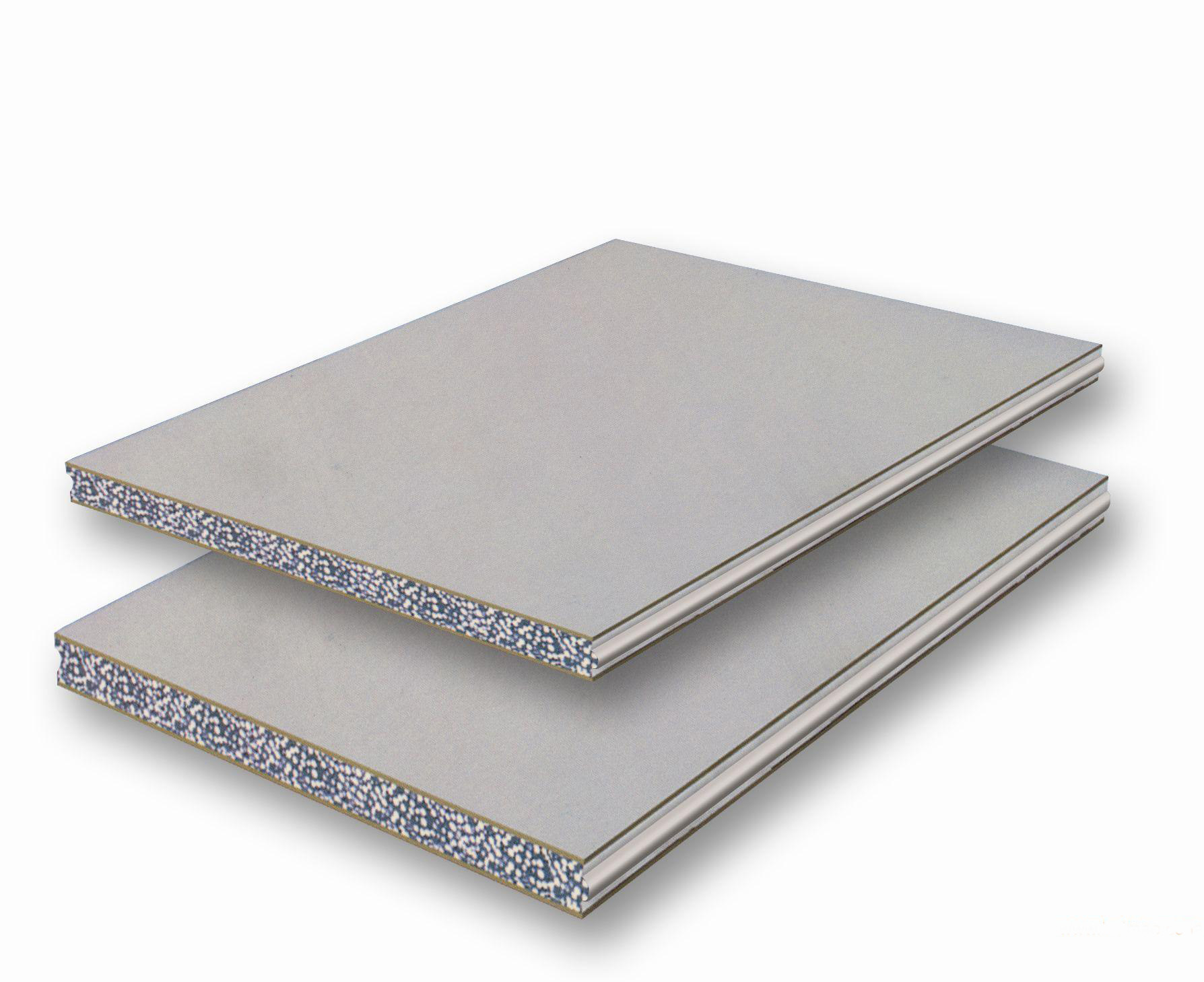

2、Lightweight & Space

and Cost Saving

DQ

waterproof wall panel is a kind of solid core but thin body new wall material, which

is lightweight, and greatly reduces the building's load-bearing. The thickness of

the waterproof panel is from 90-180mm, which will save a lot of space when

compared with the traditional bricks.

For

example, if plastering the traditional bricks, the general thickness will be

240mm+40mm, but if DQ panel, the 90mm thickness will be enough for partition

wall, and still meets the national testing standards.

3、 Easy Construction & Shorter Time

DQ waterproof wall panel use fabricated

way to install, which is easy and effective for installation and no

construction waste, no need to plaster and shorter the time for construction.

The traditional bricks need 12 workers

to work 60mins, but for same project, if use DQ wall panel, it just needs 3

workers to work an hour, which will save a lot of labor cost for the

construction part.

4、High intensity & Quake Proof &High

safety performance

DQ waterproof wall panel use fabricated

way to install, which has strong intensity as a whole, and the seismic

performance is much higher than that of the traditional walls dozens of times,

and also some times higher than it regarding the anti-impacting.

Under the impact force of 50 kilograms, no

slightest transfixion crack, no deformation and no surface loose marks, DQ

lightweight partition panel can be directly nailing or bolts for hanging heavy

objects, such as fire hydrant, lampblack machine, water heater, etc.

Technical Index

|

No.

|

Items

|

National

Standard

|

Testing

Result

|

|

60mm

|

90mm

|

120mm

|

60mm

|

90mm

|

120mm

|

|

1

|

Anti-impact

Capacity/times

|

≥5

|

≥5

|

≥5

|

≥8

|

≥10

|

≥15

|

|

2

|

Anti-bending

damage load/times over dead weight

|

≥1.5

|

≥1.5

|

≥1.5

|

≥3

|

≥4

|

≥5

|

|

3

|

Compressive

Strength /Mpa

|

≥3.5

|

≥3.5

|

≥3.5

|

≥5

|

≥5

|

≥5

|

|

4

|

Softening

Coefficient

|

≥0.80

|

≥0.80

|

≥0.80

|

≥1

|

≥1

|

≥1

|

|

5

|

Surface

Density/Kg/㎡

|

≤70

|

≤90

|

≤110

|

≤55

|

≤70

|

≤85

|

|

6

|

Moisture

Rate a/%

|

≤12/10/8

|

≤10/9/7

|

|

7

|

Drying

Shrinkage Value /mm/m

|

≤0.6

|

≤0.6

|

≤0.6

|

≤0.45

|

≤.0.5

|

≤0.06

|

|

8

|

Single Point

Hanging

Strength /N

|

≥1000

|

≥1000

|

≥1000

|

≥1200

|

≥1300

|

≥1500

|

|

9

|

Sound

Insulation Capacity in the air /Db

|

≥30

|

≥35

|

≥40

|

≥35

|

≥40

|

≥45

|

|

10

|

Fire Proof

Limit /h

|

≥1

|

≥1

|

≥1

|

≥2.5

|

≥3

|

≥4

|

|

11

|

Heat

Transfer Coefficient b/w/m2

|

|

|

≤2.0

|

|

|

≤2.0

|