Cooperative project

1, Wuhan Metro Line 2/4/6

2, Wuhan Tan Hualin

3, tiesiyuan design headquarters building

Product introduction

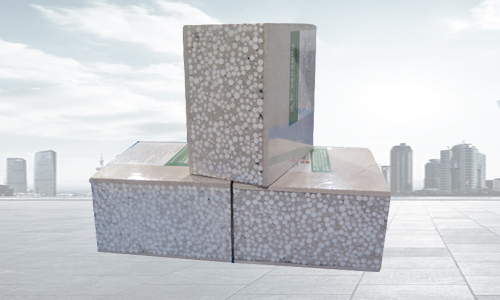

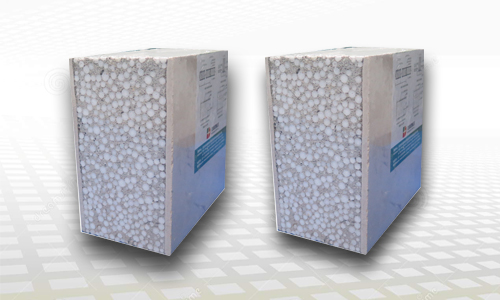

The right of DQ composite sandwich panels with cement or calcium silicate board fiber reinforced calcium silicate board as the middle panel, filled with cement, EPS EPS, sand and other lightweight core material of a composite formation. It marks the birth of the wall material replacement - to replace the traditional block, it is a new concept with excellent performance to meet the requirements of the modern building environment.

Application range

1) is widely used in all kinds of old and new construction of non - bearing inside and outside the partition wall;

2) applicable to industrial building fire partition wall and internal and external non bearing partition wall;

3) applied to the internal and external walls of steel structure building;

4) applicable to the transformation of the old floor floor of the load-bearing requirements of the building wall;

5) suitable for fire prevention, sound insulation and moisture proof;

Product features

1, energy saving, green environmental protection

DQ composite sandwich panel using freeze resistant insulation material of environmental protection, has good heat insulation function, with seasonal climate change and automatically adjust the moisture content of the air, the indoor temperature is kept at a constant level, to achieve the ecological effect, accord with the development trend of modern eco residential residential building.

2, waterproof, fire

DQ composite sandwich panels at high temperature of 1000 degrees Celsius for 4 hours, the fire retardant properties of up to the national level a standard, and the material does not emit any toxic gas, fully integrated international environmental standards;

DQ composite sandwich panels without the need to touch the ash can be made into a container filled with water, without any leakage.

3, sound insulation and sound absorption

DQ composite sandwich panels with good sound insulation and sound absorption function, sound volume reaches right 90mm thickness is 45dB, the traditional block noise volume is 20dB.

4, light weight, saving space, reduce costs

Weight weight light partition board is a kind of new wall material with solid core and light weight, which greatly reduces the weight of the building. The thickness of the finished product is 60mm-180mm, and the building space is greatly saved compared with the traditional block thickness. For example: the traditional building block with an average of 240mm+40mm, while the weight of light partition wall plate 90mm thickness of the wall partition can meet all the requirements and meet the national standard.

5, construction is convenient, shorten the time limit for a project

The construction of the DQ composite sandwich plate is assembled by the construction of the right, the whole assembly or the construction process is simple, high efficiency, no construction waste, no need to touch the ash, shorten the time limit for a project. Traditional block wall requires 60 people to 12 minutes of construction weight of lightweight partition board as long as 3 people can be completed 60 minutes for the construction side to save a lot of labor costs.

6, high strength, shock, high safety performance

The right of DQ composite sandwich board adopt assembly type construction, the overall strength is high, the seismic performance of masonry wall is higher than that of dozens of times, several times the impact performance as well as other masonry, the impact force of 50 kilograms, without the slightest through crack, no deformation, no traces of strong surface loose; lightweight partition board can be right direct nailing or expansion bolt hook hanging weights, such as air conditioners